Higher energy yield from wind farms – launch of “CompactWind II”

On 7 December, the partners from the research project “CompactWind II”, in which eno energy systems GmbH is also involved, met for the kick-off in Hamburg. The joint project will be funded by the Federal Ministry for Economic Affairs and Energy (BMWi) with a total of 1.4 million euros over the next three years.

The aim is to use new control concepts to reduce the so-called wake effects in wind farms and thus gain more power. Under the leadership of eno energy, the University of Oldenburg with the Centre for Wind Energy Research (ForWind), the Chair of Wind Energy at the Technical University of Munich (TUM) and fos4X GmbH, Munich, are involved.

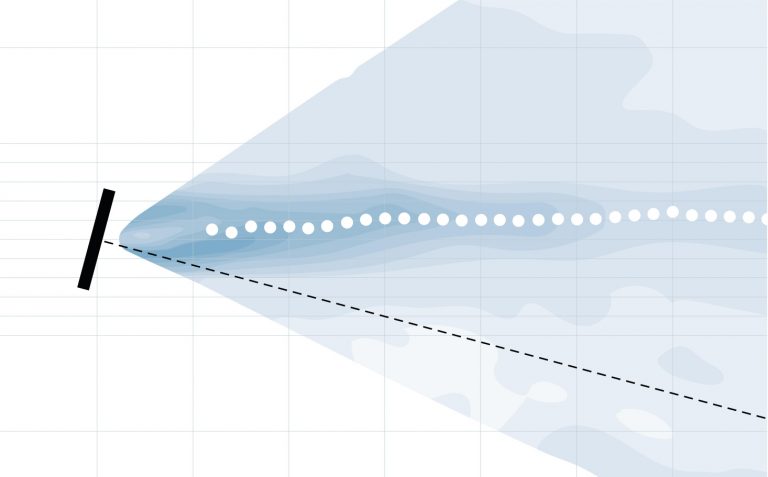

In order to make optimum use of the available area when expanding onshore wind energy, several wind turbines are usually grouped together to form wind farms. In a group of turbines, unfavourable flow conditions occur behind the turbines depending on the wind direction. In the so-called wake behind a wind turbine, lower wind speeds and stronger turbulence prevail. This means that the turbines encountered in the wake generate less energy and are exposed to higher structural loads. These negative wake effects are exacerbated by the fact that new turbines with larger rotors are installed at closer distances from each other, as the site area is limited. The “CompactWind II” project aims to minimise the negative influences of wake in order to increase the energy yield and reduce the loads. This would make it possible to achieve more power with the same footprint of the wind farm. This is why the project title “CompactWind II” was chosen.

One way to reduce the effects of wake is to deflect the wake. With this approach, individual turbines are deliberately turned about 10 to 20 degrees out of the wind direction so that the wake does not hit the next turbines to the full extent. In the successfully completed predecessor project “CompactWind”, the potential of a targeted influence on wake was already demonstrated through extensive open-field tests in an eno energy test wind farm. In the follow-up project that has now been launched, the concepts are to be further developed and tested in a wind farm with four turbines. The research results should help to use the limited space for wind turbines more economically, efficiently and in a more environmentally friendly way in the future.

Over the next three years, the project partners want to test the new control procedures with the most modern methods available using computer simulations, model tests in the wind tunnel as well as field experiments on real turbines. For the project, eno energy systems is providing current wind turbines with an output of 3.5 megawatts and a rotor diameter of 126 metres at the Kirch Muslow wind farm in Mecklenburg-Western Pomerania. It will implement the new control procedures and evaluate them for their practical suitability.

The TU Munich will test a wind field observer in the open field, which can derive from the operating data of the wind turbines whether and where in the rotor surface a wake is encountered. Via feedback to the turbine upstream, its wake can then be optimally deflected. Fibre-optic blade sensors from the company fos4X GmbH are to record the material loads on the rotor blades and thus provide important data for control and operational optimisation. Laser-optical lidar measuring devices from ForWind are to record the wind conditions and wake flows over large distances without contact. In addition, scientists from ForWind and TUM are developing even more advanced control approaches through simulations on high-performance computer clusters and in model tests in the turbulent wind tunnel in Oldenburg.

Shaping tomorrow's future today

The eno energy Group is Europes leading medium-sized manufacturer of premium wind turbines. At our locations Rostock and Rerik, we develop and produce durable and powerful onshore wind turbines in the 2.2 to 6.0 MW range.

Due to our first-class quality “Made in Germany” and innovative know-how, we are offering individual solutions to our customers. Based on our product portfolio, our international sales pipeline and our constantly growing network, our environmental and social philosophy of sustainable and responsible behaviour drives us forward every day.