Optimising the 6 MW platform

The team at eno energy systems GmbH has spent the last 20 years developing high-quality, robust wind turbines, driven by passion, a thirst for knowledge and strong expertise. Not only can they draw on experience in operation and development, they also address any problems that arise during project development. ›››

The internal feedback loop that links the various parts of the company, connecting project development, project management, development, operations management and service, makes it possible to respond to the requirements of other departments while developing a turbine.

Wind turbine noise emissions are a topic that has become increasingly important in recent years as rotor diameters have grown. The majority of turbines now in the project planning phase are subject to night-time reductions in noise levels imposed by the authorities.

The noise emissions of a wind turbine are largely determined by the blades; the faster they turn, the louder they are. In order to meet noise limits, it is often necessary to reduce the rpm at night.

However, when rpm is reduced, so is generator voltage. If the generator voltage falls too far, the turbine can no longer supply electricity because the grid inverter is not receiving the necessary input voltage.

While the electrical excitation of the generator can be amplified to adapt the low generator voltage in the partial rpm range to the high voltage in the grid inverter, this leads to very high losses in the generator.

These losses need to be dissipated, or the generator will overheat, but this is only possible to a limited extent without sophisticated cooling systems.

6 MW platform power-up

when rpm is reduced at night

to comply with noise limits

Consequently, in initial noise level predictions, power was reduced when electrical excitation was high, to the point where overheating was avoided.

A second option for aligning low generator voltage with high grid inverter voltage is the use of a step-up converter. This adapts the rectified generator voltage to the grid inverter voltage.

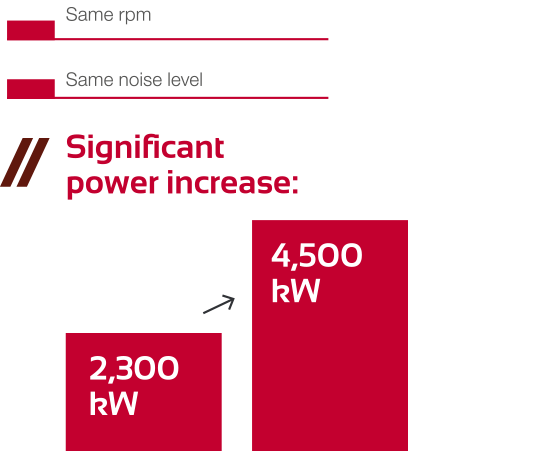

In the first stage of developing the 6 MW platform, the step-up converter was unable to handle the output of the eno152/160 in reduced-noise operation. Fortunately, the development team found an innovative way to double the transferrable power of the step-up converter, such that the converter no longer causes a power output bottleneck in reduced-noise operation.

Consequently, it is possible to align the generator voltage with the grid voltage, even when output is high, without the need to increase electrical excitation of the generator. The resulting reduction in generator losses means that more output can be demanded of the generator while keeping losses the same and supporting the sound modes developed as part of the latest update.

In summary, the output at different rpm speeds has been significantly improved, with an almost 100 per cent gain being seen in the important medium rpm ranges. Optimisation, critical scrutiny of predictions and constant learning all help to improve wind turbines throughout the course of their development, to design them in a way that makes project planning easier and to maximise the performance of the enoventum platform for developers, operators and for feed-in management.

Please contact us to find out more!

“Progress is the fruit of dissatisfaction”

Jean-Paul Sartre,

French author and philosopher